FDM vs SLA - Which 3D printing technique should you use?

Dec 12, 2023

Let’s start with a story…

A father was sitting in the kitchen trying to make a toy for his young daughter. He took a glue gun and started to put together a loosely formed shaped with the melted glue. Multiple layers of glue slowly began to take the shape of a frog. During this process, the father realized that this experiment could be extended to bigger projects.

Scott Crump (the father) invented a method of 3D printing known as FDM (Fusion Deposition modeling). It is one of the most extensively used processes in the 3D printing industry. We at Fabheads also use this method to build prototypes, tools, and parts for our customers.

3D printing can be done using multiple processes. FDM and SLA are two of the most common procedures in the additive manufacturing industry. We will look into each one of these techniques by examining various characteristics. Here is a list of the topics that this article will delve into.

- A brief history of 3D printing

- The working process of FDM and SLA

- Characteristic comparison of FDM and SLA (design, print quality, material, etc. )

- Applications of FDM and SLA

- Which method should you pick?

A brief history of 3D printing

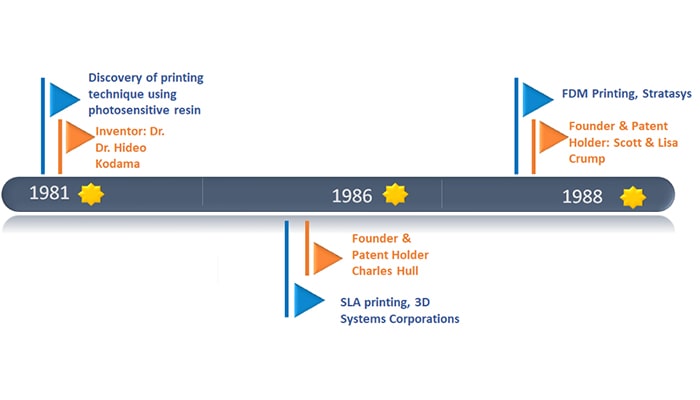

3D printing had a fascinating journey. Starting from the 1980’s it has evolved and taken shape with improvement in technology. Let’s take a closer look at the timeline of 3D printing. This will help us understand the different types of printers and processes that came about.

The Inception & Discovery

Stereolithography Apparatus (SLA)Technique

Since the 1970’s 3D printing was on its verge of inception. Dr. Hideo Kodama was finally successful in attempting a method for rapid prototyping. He used a photosensitive resin and polymerized it by using UV light. In 1981, he became the first person to come close to explaining the layer-by-layer approach of printing a 3D object. This process is now known as SLA or Stereolithography apparatus.

A few other engineers worked with this method. However, they were falling short of a business idea that would help with the practical application of the process. In 1986, Charles Hull secured a patent for SLA printing and formed a company called 3D Systems Corporation. The company was the first to build an SLA printer for commercial use.

Fusion Deposition Modeling (FDM) Technique

As mentioned in our little story at the introduction — In 1988 Scott and Lisa Crump stumbled upon an interesting technique while trying to create a toy frog for their daughter. They were using a hot glue gun with polythene and candle wax. This sparked an idea to create an entire set-up that would melt filaments and form a 3D object. They went ahead to secure a patent for FDM (Fusion Deposition Modeling) printing methodology and founded a company called Stratasys.

The Working Process

Stereolithography Apparatus (SLA)

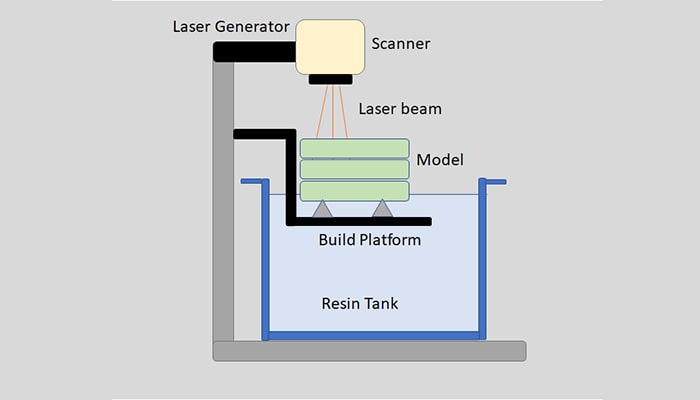

In simple words, SLA uses light on photopolymer resin that chalks out the shape of the 3D object. The solidification of liquid resin is called photopolymerization. The build platform moves downwards to print the model one layer at a time. It goes into the surface of the tank to coat itself with more resin. This process is repeated until the 3D model is completed.

Fusion Deposition Modelling (FDM)

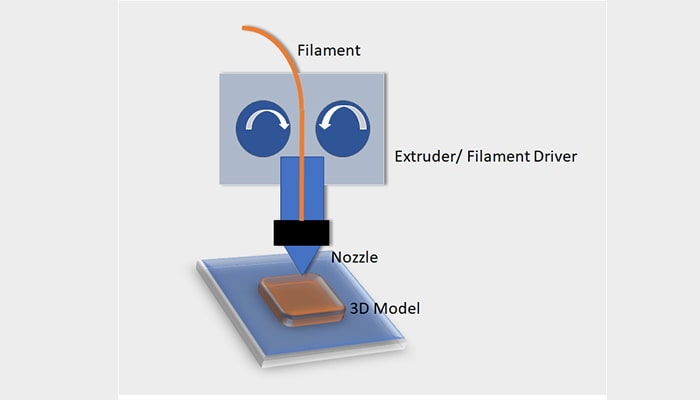

It is an additive manufacturing process that combines layers of material to form an object. A filament is melted using heat. The melted filament oozes out of the nozzle and settles on a print bed. After several rounds of repetition, the 3D model is formed layer by layer.

Characteristic Comparison – FDM and SLA

We will look are various characteristics in 3D printing across both these processes.

- Design

- Print Quality

- Materials

- Print Speed

- Printing Cost

- Adhesion and Post Processing of Prints

1. Design

When it comes to manufacturing, the design of the product becomes the guide of the project. Design involves detailed planning and projection of your final model. FDM and SLA techniques have elaborate design practices that one must follow.

FDM

In this method of printing, it is important to note that the process can be slightly iterative. You may need to print prototypes and make design changes on the go. Following are some key points to keep in mind while you design your FDM print.

- Tolerance — the dimensional tolerance for FDM is ±0.15 % and a lower limit of ± 0.2 mm

- Gaps — if you have gaps in your design, it is important to maintain a width >2mm

- Wall thickness— In FDM printing the minimum wall thickness is approx. 1 mm. this is primarily dependent on the size of the nozzle. The thumb rule is that features that are thinner than x2 of the filament’s thickness can lead to a bad print.

- Holes — if you have incorporated holes in your model, it is important to keep the diameter >1 mm. This would help in the retention of its shape.

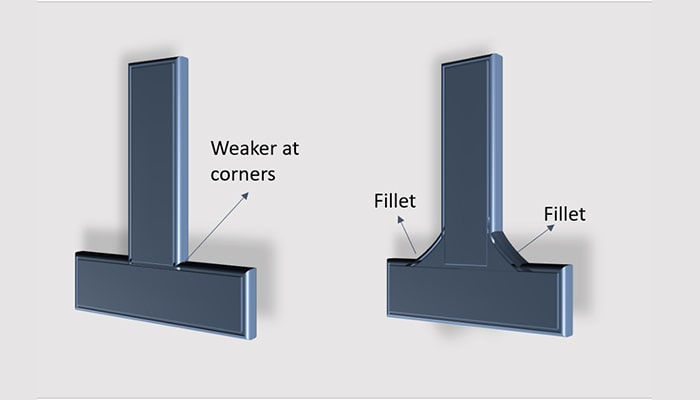

- Support structures — Especially for overhanding structures that are positioned at an angle >45 degrees from the vertical. A fillet will provide continual support.

- Fillets —Sometimes adding the fillets can help in strengthening fragile features in the model. They can help minimize the support structures.

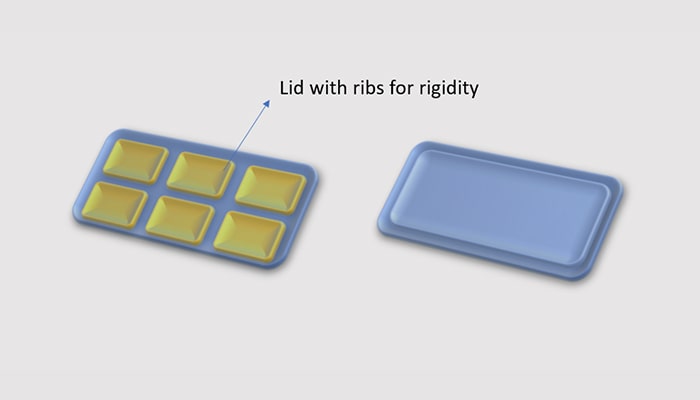

- Add Ribs — Just like fillets, ribs can be used to improve the strength of your product. It helps in the even distribution of the force applied to the surface of the model. A minimum rib thickness to be maintained is 0.06 in.

SLA

SLA method is great at printing models that have intricate design details. Similar to FDM, some factors need to be considered before printing. Following are some design elements to keep in mind.

- Tolerance — SLA printing has a dimensional tolerance of ± 0.15% and a lower limit of ± 0.01 mm.

- Wall thickness — To prevent any kind of warping, the minimum thickness for SLA printing is 0.5 mm.

- Holes — if you have incorporated holes in your model, it is important to keep the diameter >0.5 mm. This would help in the retention of its shape

- Support Structures — Compared to FDM, in SLA there is relatively less requirement for support structures. However, it is recommended to provide support structures for models that are placed at least 19 degrees from the horizontal for overhangs.

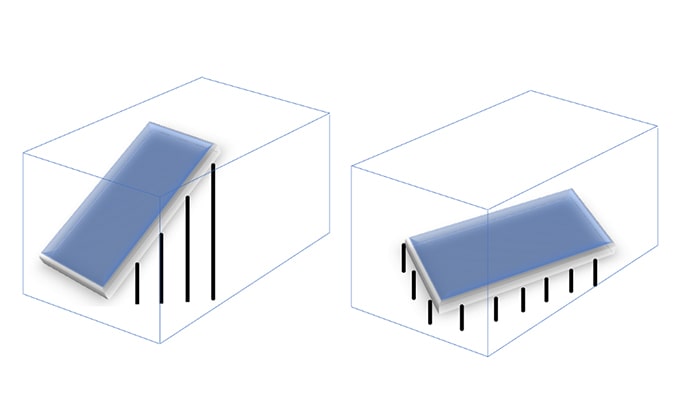

- Orientation — The z-axis cross-sectional area is a cause of concern in SLA. There is a high chance for the print to stick to the walls of the tank if the z-axis cross-sectional area is high. This can be controlled by reducing the area along the z-axis.

2. Print Quality

In FDM prints, its resolution is dependent on the size of the extrusion nozzle. Moreover, the movement of the extruder along the X/Y axis has a huge impact on its quality. Therefore, for FDM printing the quality of the print lies in the calibration of the printer for most cases.

Another key point to note in FDM printed objects is that the weight of upper layers compresses the lower layers. FDM prints are dependent on the mechanical bonds between the layers. Hence, proper alignment and design considerations can lead to a better quality of the 3D prints. The surface finish of the products is usually rough and rigid.

Coming to SLA, the accuracy and precision of prints is slightly higher. The resolution of the print is solely dependent on the light source. Unlike FDM, the force applied on different layers is relatively less. SLA printing is primarily based on chemical bonds via cross-linking of photopolymer across the layers. This results in the isotropic nature of the printed parts. Here the surface finish is smoother.

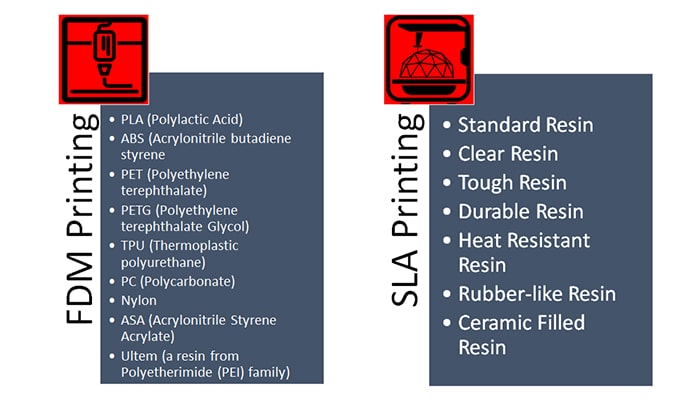

3. Materials

4. Print Speed

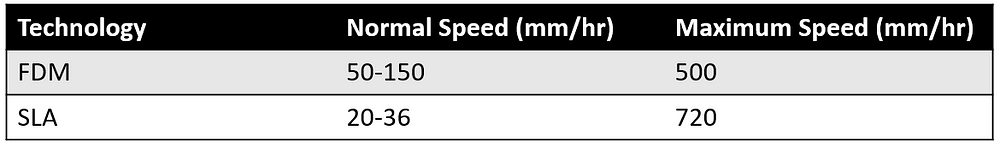

The printing speed varies based on the build quality of the printer and also the material used. The speed of the printers is measured in millimeters per hour. For FDM it is noted that the average speed is ~100 mm/hr. This means that it can print a deposit of 100 mm in about an hour. FDM printers (depending on the printer) can go as fast as 500 mm/hr. SLA 3D printers are known to achieve a high speed of up to 700 mm/hr.

5. Printing Cost

FDM printers are much cheaper than SLA printers. Post the initial purchase, the overall printing cost is dependent on the materials used. In this case, FDM printers use PLA or ABS-based filaments which are cheaper when compared to resins that are used in SLA printing. 1 kg of PLA costs about $15 (approx. ₹800–₹1200). 1 liter of standard resin can cost around $40-$150 (approx. ₹2500–₹12000).

6. Adhesion and Post Processing of Prints

While talking about the manufacturing of 3D prints, the adhesion to print beds is an important aspect. In FDM printers, the printed objects are easily detached using a pallet knife or other tools. However, when it comes to SLA printers, removing the model from the print platform can be challenging. The resin tends to stick to the platform.

Removal of the support structure is also part of the post-printing process. In some cases for FDM printers, the supports are soluble or can be removed using cutting tools. For SLA printing, the support systems can be removed with the help of isopropyl alcohol.

Applications

Depending on the characteristics discussed in the previous section, various industries have adapted these printing techniques to suit their requirements.

FDM

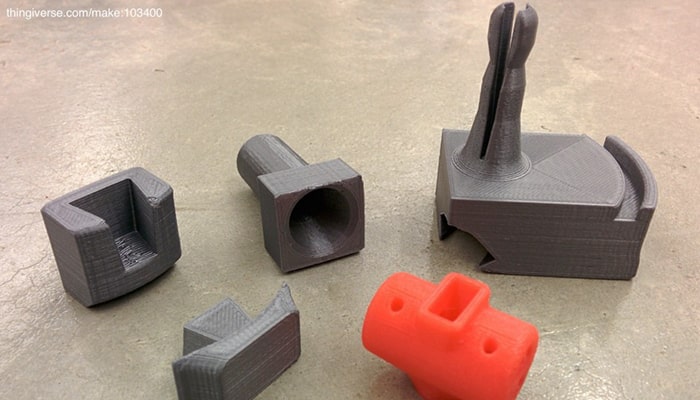

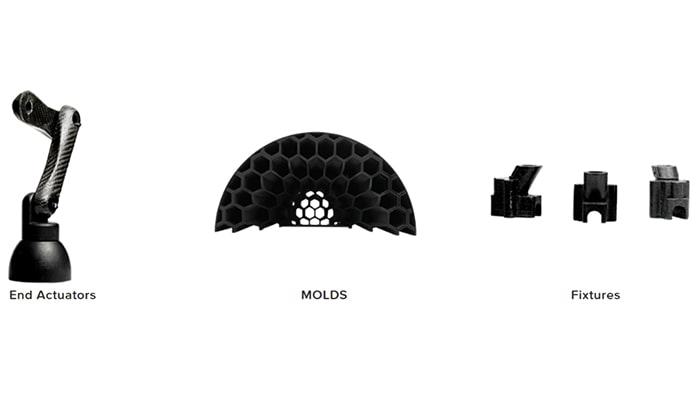

In this technique, it is easy to achieve consistently accurate geometry. The printed parts have good stability and strength. Also, the use of thermoplastics makes it lightweight. FDM printing applications cover a diverse set of industries — automotive, medical, construction, sports, aerospace, military, etc. The automotive and aerospace industries are heavily dependent on FDM printed parts. FDM is used for printing prototypes and final parts.

Here is a picture of a low-cost FDM printed prototype for motorbikes. It is made out of high-strength ABS thermoplastics with functional parts.

SLA

In this technique, it is easy to achieve products with intricate details. It has the ability to produce durable objects. It is capable of giving a smooth finish and high precision. SLA is great for creating molds and casting patterns. It is used in the dental field extensively to create dentures. Since SLA uses resins for production, it is used for the creation of optics and transparent covers. SLA printing is used across many industries — Healthcare & Medical (predominantly dental), entertainment, architecture, audiology, jewelry designing, etc.

Which method should you pick?

FDM and SLA printing techniques have a wide range of applications. It is not possible to pick one style of printing over the other without understanding the requirements of the product’s end-user.

It is important to consider various factors like — production cost, time frame, and product design. FDM is capable of producing products that have a simple design and low cost. Whereas, SLA can nail detailed designs in a shorter span of time with high production costs. Therefore, while picking the printer or the process, it is important to understand what each of these techniques offers.

Both the techniques are part of current manufacturing processes across different industries. Many of the companies use a combination of these two printing methods. Therefore, it is important to take into consideration of various advantages that each of these processes offers. Throughout this article, we have viewed different parameters that can help the manufacturer reach a conclusive solution (while choosing the process).

Conclusion

Be it SLA or FDM printing, 3D printing has come a long way within a few decades. The story of 3D printing that began in the 1970s has penetrated various industries over time.

In examining the differences and similarities between SLA and FDM, a product designer or manufacturer can learn to make the right decisions for their user. In our discussion, we attempted to give the readers a fundamental understanding of the two processes.

We understood the workflow and basic methodology, print characteristics like — design, print quality, materials, print speed, printing cost, adhesion, and post-processing; and the applications of both FDM and SLA processes. We can see that both these techniques solve major problems that manufacturers face. The processes will continue to evolve and help future generations solve more complex hurdles.

Please let us know in the comments, which technique would suit your manufacturing process and why?

Fabheads uses its in-house Continuous Fiber 3D Printer Series — FibrBots to create drone parts, manufacturing tools, etc. For more solutions on composites and other manufacturing technologies, visit our website fabheads.in