Present and Future of 3D Printing

Feb 18, 2022

The Industry 4.0 revolution speaks highly about 3D printing technology. Experts say that additive manufacturing techniques will become more integral to various industries across the globe in the coming years.

Although 3D printing has been part of manufacturing since the early 1980s, it’s not until recently that the entry cost for 3D printers has reduced significantly. This makes embracing 3D printing an efficient and smart choice in today’s age of digital manufacturing.

In this article, we will examine the present and future state of 3D printing. We will also look into some real-world examples that exemplify the extensive use of 3D printing. A brief overview of some aspects that will be covered in this reading—

- 3D printing usage— Its widespread reach

- Industrial applications across various sectors (Aerospace, Automobile, Drones, Medicine, and Construction)

- Market potential and growth

Without wasting any further time let’s get into it…

3D Printing Usage— Its widespread reach

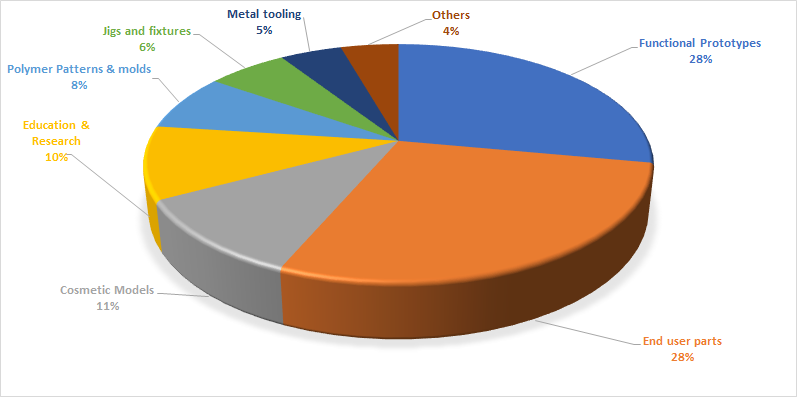

When 3D printing first entered the markets, it was a tool predominantly used for prototyping. The choice of materials was limited and hence, companies were able to make low-cost plastic-based prototypes. However, with more research and technological improvement in the process and material choice, 3D printing sees itself at its pinnacle of success in the present. The chart below depicts the various ways in which 3D printing is used in industries.

The uses of 3D printing can be categorized into the following:-

- Prototyping

- End-use parts

- Tooling

As we can see from the chart, the applications of 3D printing have now become more diverse. The shift from prototyping to other widespread applications indicates that 3D printing will continue to grow. The growth is visible as 3D printing becomes a key component in industries such as aerospace, drones, automotive, medicine, defense, architecture & construction, etc.

Industrial applications across various sectors

1. Aerospace

Aerospace has been using 3D printing since 1989. In recent times 3D printing has seen rapid growth in this sector. Following are some factors that are critical in the aerospace industries —

- Fast delivery

- Low production quantity

- Possibility to DfAM (Design for additive manufacturing)

These aspects are pivotal in the reduction of the overall weight of the aircraft. This substantially cuts costs and prevents excess emission of CO2. 3D printing finds itself to be a key component in the aerospace supply chain, here is how:

Design: The software and technology behind 3D printing give designers a lot of freedom to try and test out new designs. The mode of producing parts can vary from creating 3D printed molds, casts, and direct prints. Designers have a lot of flexibility with 3D printing. They can transfer the 3D CAD files to actual prints and also implement changes on the go.

Prototyping: Conceptualization of designs is necessary to showcase the usability of certain models in aerospace manufacturing. It also has to be subjected to aerodynamics testing. This is why one needs high precision and functional prototypes. 3D printing makes this task fairly easy due to its advanced printing techniques such as FDM (Fusion Deposition Modeling), SLA (Stereolithography), or Material Jetting.

Customization: It is common in aerospace to have customized components for a particular design. 3D printing makes customization easy, quick, and formidable.

“The average corporate aircraft travel 75,000 miles per month and a single component that was designed and manufactured with 3D printing reduces air drag by 2.1%, reducing fuel costs by 5.41%”

— hubs.com

So what are some common components that are manufactured using a 3D printer?

- Jigs & Fixtures — with 3D printing of these components, there is an almost 60 to 90 percent cost reduction and improvement in lead time in comparison to conventional manufacturing processes.

- Surrogates — much like the prototypes, act as the placeholders that are to be replaced in the final stages of assembly. 3D printing surrogates is cost-effective.

- Mounting brackets — as metal 3D printing emerged, these metal mounting brackets are now manufactured with ease.

- Wings, blades

and much more…

Real-World Examples of 3D printing in Aerospace

Recently, Airbus Services assembled metal-printed flying spare parts using additive manufacturing (3D printing) for an Airbus A320eco. It is one of the oldest aircraft. Wingtip fences of this aircraft are no longer in active production. However, with the help of 3D printing, Airbus Services can now manufacture and deploy new spare parts to some of the oldest aircraft.

3D printing also has a huge role in building space rockets. Stargate is one of the largest metal 3D printers that is used by companies like Relativity Space to print an entire rocket.

2. Automotive Industry

Automotive industries use 3D printing extensively for prototyping, tooling, and end-parts production. Additive manufacturing or 3D printing has opened a pandora’s box. It is now possible to manufacture new designs and clean and lightweight products without compromising safety. 3D printing also gives shorter lead time and low cost. 3D printing capabilities have shifted from rapid prototyping to manufacturing end goods directly in automotive industries. Let’s walk through some benefits of 3D printing in the automotive industry…

- Rapid prototyping improves the quality of automobiles

AM or 3D printing is perfect to create prototypes. Rapid prototyping ensures good quality testing for the actual products. The design flexibility in 3D printing allows the building of functional and durable prototypes. General Motors uses 3D printing techniques like SLS ( selective laser sintering) and SLA (stereolithography) to make prototypes of around 20,000 components.

- Customization of tools

Tooling in automotive needs to be specific, consistent, and high quality. 3D printing helps achieve this due to its versatile nature. With 3D printing, one can manufacture customized tools that would improve the work and productivity on the shop floor. BMW has incorporated AM or 3D printing to deliver custom-built, handmade tools which are 72 % lighter than the existing tools.

“The customized tools helped save 58 percent in overall costs and reduce project time by 92 percent”

— BMW

- Aiming to achieve maximum weight reduction

Weight reduction of vehicles is correlated to the fuel efficiency of vehicles. Using lightweight parts can go a long way in this effort. Many manufacturers have started to replace parts of the aluminum body with carbon fiber-based materials. Ford’s F-150 fits the bill perfectly. In 2014, the vehicle’s body was made out of aluminum. After replacing it with carbon fiber, the weight was reduced by 317 kgs.

Kevauto Licensed under CC BY-SA 4.0)

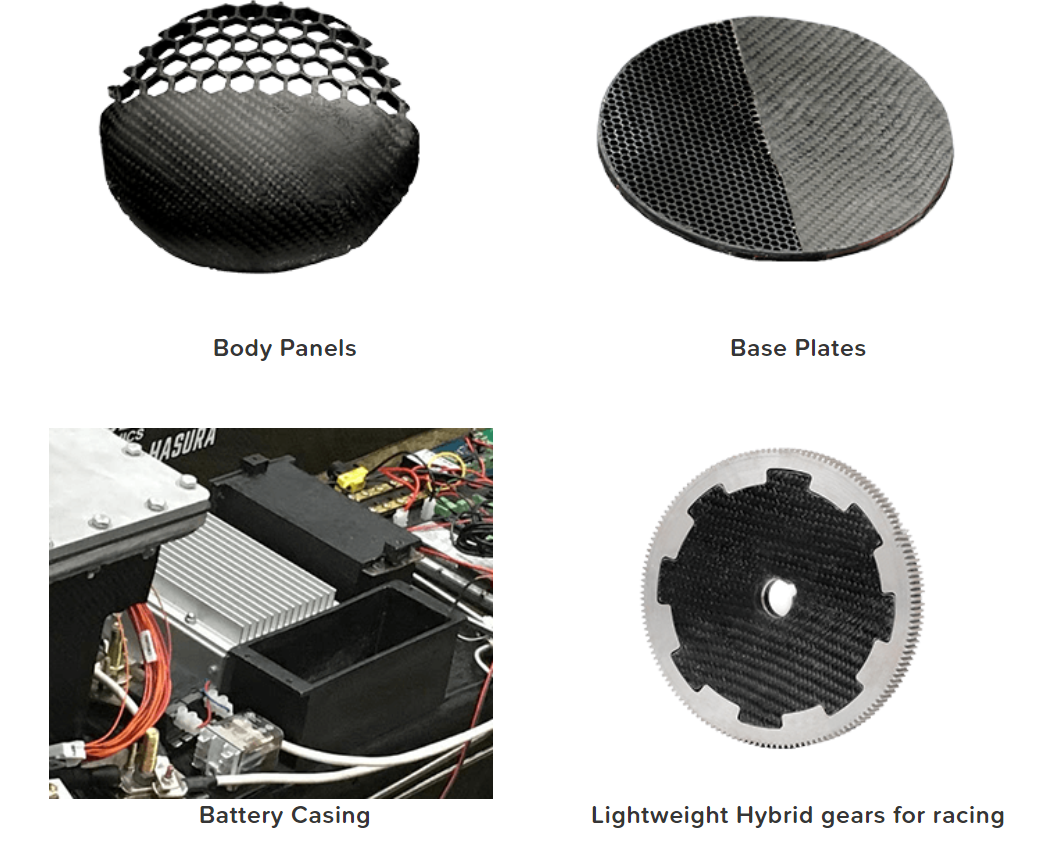

Fabheads also uses its in-house fiber3D printers (FibrBots) to print parts of automobiles using carbon fiber. Carbon fiber is high in strength and lightweight, which is ideal for automobiles. It helps with fuel efficiency and overall cost reduction.

The future of 3D printing in the Automobiles Industry is bright!

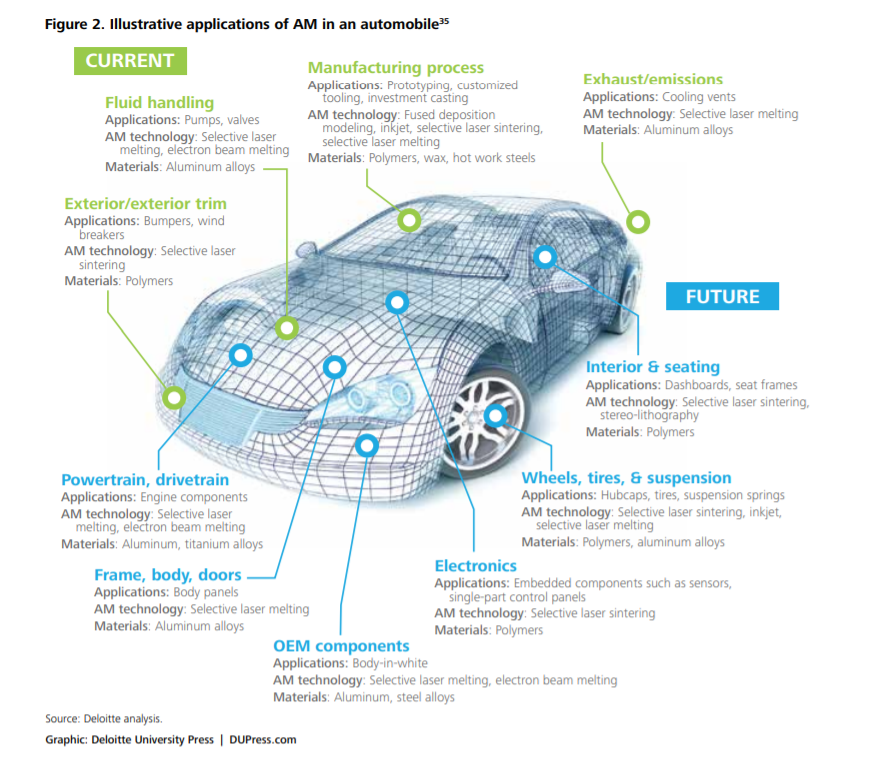

The image below shows the present and prospects for Additive Manufacturing (or 3D printing) in the automobile sector. From the “future” block we can see that there is a huge potential for 3D printing technology to take over the production of interiors, seating, powertrain, drivetrain, etc.

3. Drones (UAV)

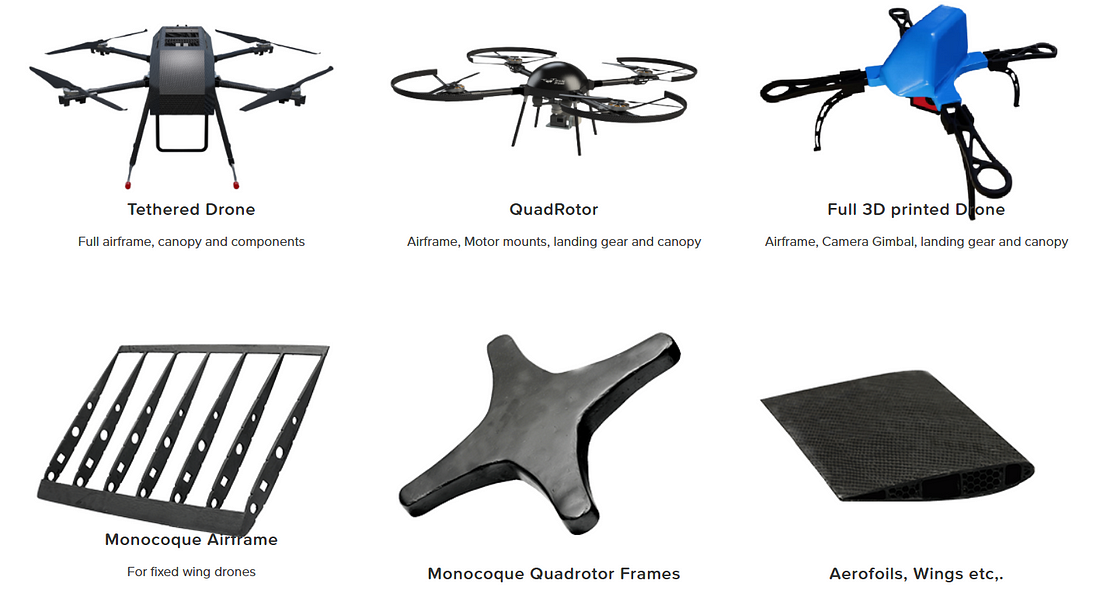

Although technically a part of Aerospace, Unmanned vehicles are becoming more popular with their widespread applications, hence can be categorized separately. Drones are being used in construction, agriculture, photography, delivery, security, etc. This is why 3D printing techniques are being used here to build customized drones to suit the individual’s requirements. It is possible to 3D print all parts of the drones and assemble them. Propellers, antennas, blades, battery housing, landing gears, etc can be easily 3D printed using the desired material.

“With 3D printing, we were able to save 40% of time in the product design and development process. The total weight of the drone was also reduced by a factor of 20%.”

-3dnatives.com

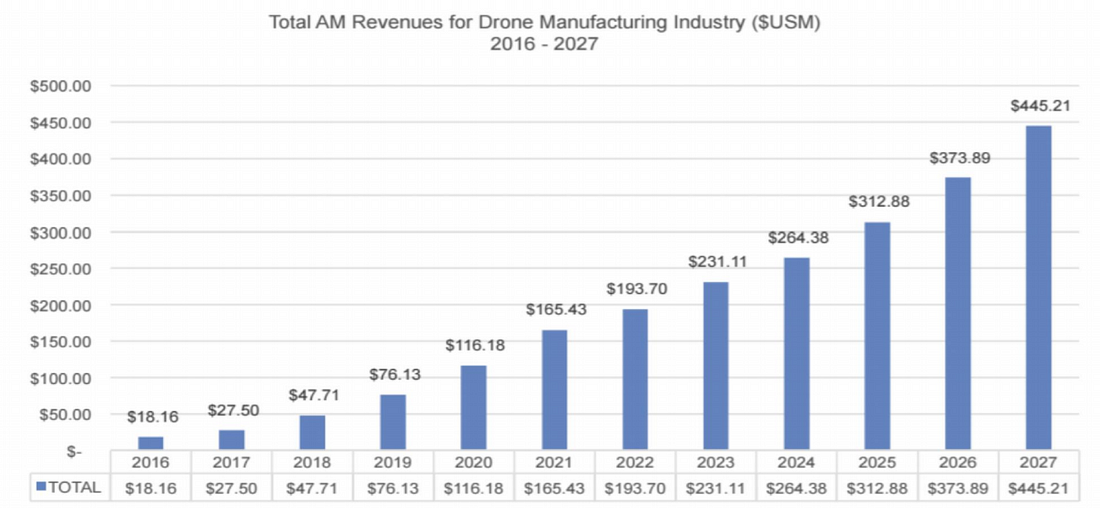

The chart below depicts the total Additive Manufacturing revenue for the Drone Manufacturing Industry. It shows the data collected and projected from the years 2016–2017. It is an indication that the drone market concerning 3D printing will continue to grow.

If you are interested in drone fabrication, check out our article where we have exclusive coverage of 3D printed drones. Also, Fabheads offers fabrication services to make full-scale drones.

4. Medicine

3D printers first entered the medical field in the 2000s. It was used for dental and customized prosthetics. As 3D printing evolved, it finds itself being used in the medical field more extensively. It is now able to produce bones, exoskeletons, jawbones, cell cultures, ears, etc. Some of the most common areas that use 3D printing are —

- Bioprinting — organs and tissues

Organ procurement for people suffering from organ failure is a lengthy process. There is a significant shortage of organs due to less number of donors. 3D printing is now capable of using the following techniques to make organs or tissues —

- Laser-based

- Inkjet-based

- Extrusion-based

In this process, the bio-ink is deposited in droplets to emulate a living cell, which will help repair or reproduce the tissues.

- Customized implants and prosthetics

3D printing can be done using an MRI scan which is converted into STL 3D print files. The printers intake the stl. file and convert it into an actual 3D model.

“In 2013, Oxford Performance Materials received FDA approval for a 3D-printed polyetherketoneketone (PEKK) skull implant, which was first successfully implanted that year.”

— Research Paper from NCBI

5. Construction

The first time that someone used 3D printing to build a wall was in 2004. A professor from the University of South Carolina attempted to create a wall using a 3D printer. This has lead to the evolution of 3D printers in the space of construction and architecture.

“The concrete 3D printing market is expected to reach $56.4m in 2021”

— 3dnatives.com

How is the construction industry using the popular and ever-growing 3D printing technology?

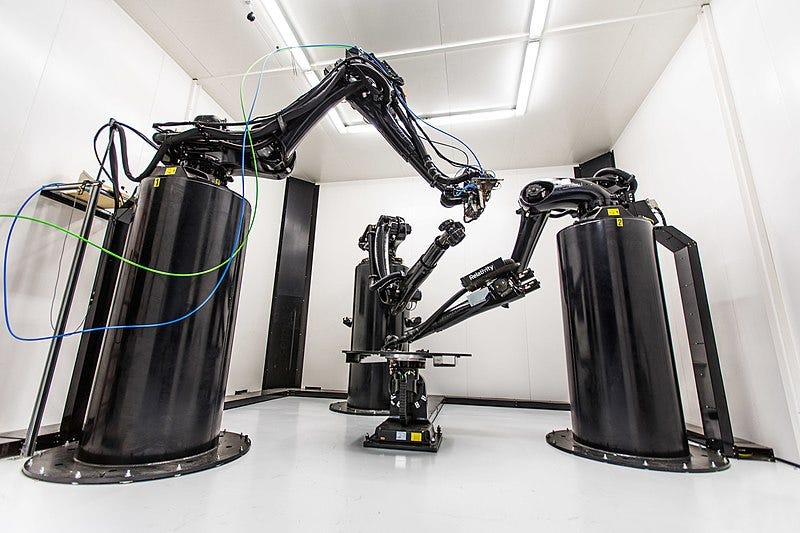

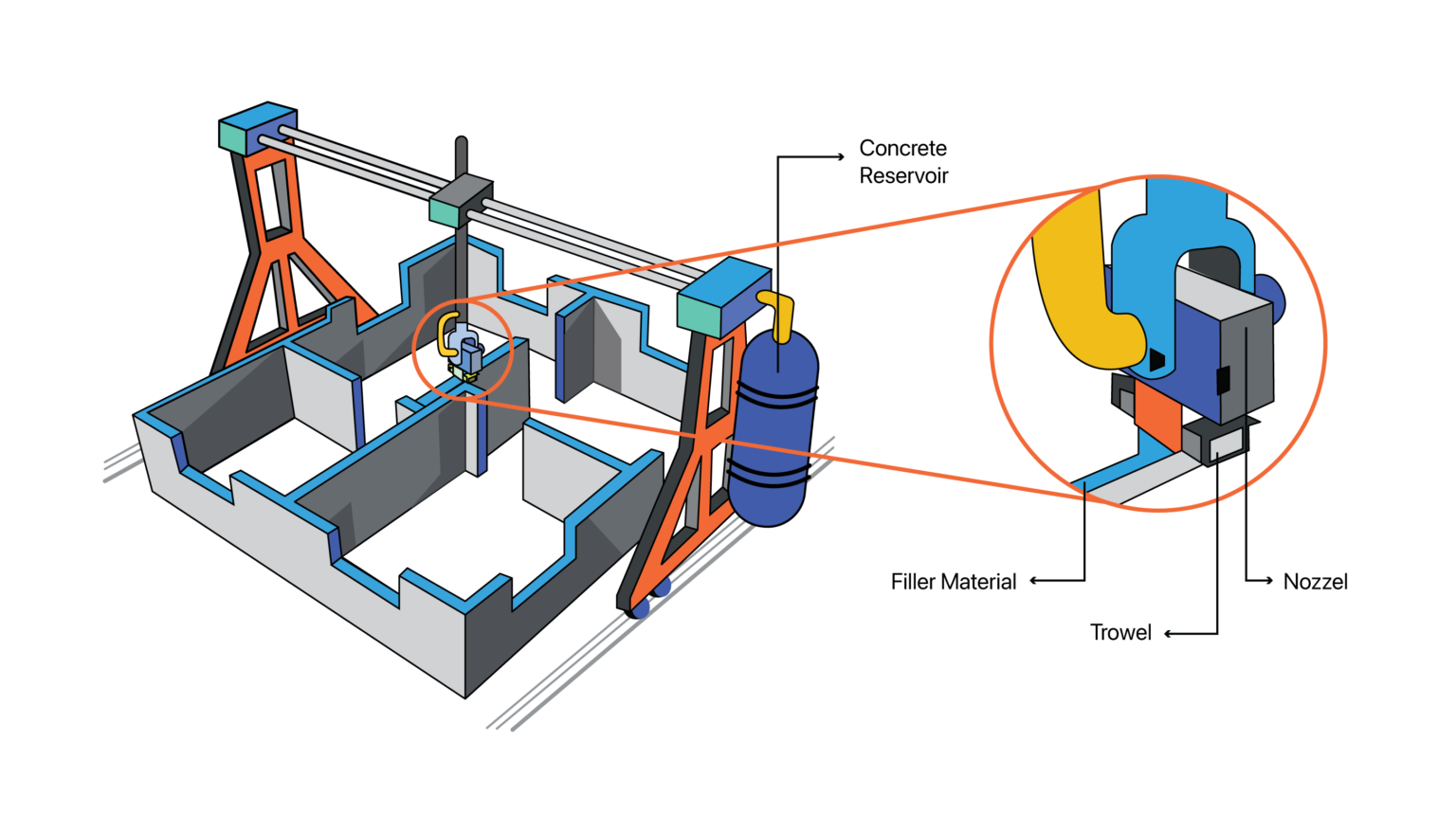

- Robotic Arm Extruders

One of the popular techniques in concrete 3D printing is called the contour crafting method. A robotic arm moves back and forth extruding the layers of concrete or mud one after the other. The nozzle oozes the given material and the trowels are used to flatten the layers.

- Sand layers

A machine called the “D-shaped 3D printer” was used by an Italian architect, Enrico Dini. Here the machine uses a powder that eventually solidifies into multiple layers one after the other. Much like the SLS method of printing. The machine is capable of making structures of size up to 6 cubic meters.

- Metal Printing

It is now possible to 3D print metal structures at the rate of 2 kilos (material) per hour. This technique was developed by a Dutch company MX3D. They named this metal printing technique as Wire Arc Additive Manufacturing (WAAM). https://fabheads.com/media/8e7b65a3bfcd588e5f7c23c36f09242e

Market growth and potential for 3D printing technology

“The global 3D printing market size was valued at USD 13.78 billion in 2020 and is expected to expand at a compound annual growth rate (CAGR) of 21.0% from 2021 to 2028”

— Market Analysis Report by Grand View Research

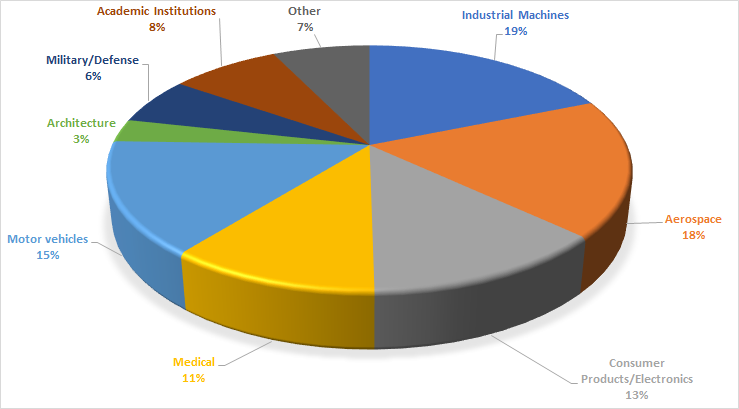

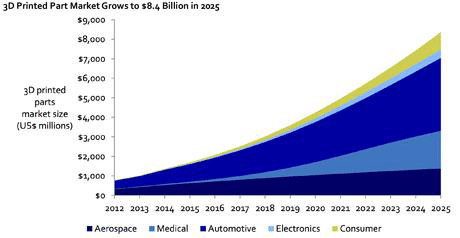

Investment in research and development is growing to improve 3D printing technology. This is due to the increase in demand across various industries such as — healthcare, aerospace, construction, defense, etc. The above graph depicts the market growth of various industries in the 3D printing space. The wide variety of printing techniques make it possible for easy adoption by different industries. The choice of materials due to varied processes has increased tremendously.

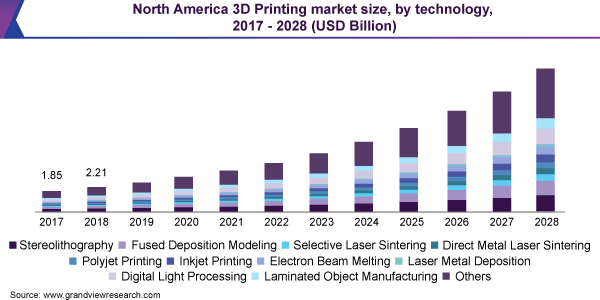

The graph below represents the projections of the various 3D printing techniques that will emerge in the additive manufacturing space in the years to come.

Conclusion

Over the years, 3D printing has spread its wings into a wide spectrum. Its low cost and quick turnaround time make it profitable. The credit goes to academia who put in intensive research hours trying to make this technology more viable and feasible across different sectors. It encourages people to build start-ups focusing on the applications of 3D printing.

We examined various industries throughout this article to understand the extent to which 3D printing is being used today. As we traversed the world of 3D printing we looked closely at the following industries —

- Aerospace

- Automotive

- Drones (UAVs)

- Medicine

- Construction

It gives us the sense that 3D printing will become more integral to our lives as the years pass by. It will encourage more people to learn and take up 3D printing technology.

Fabheads is one such start-up that is reaching new heights, thanks to its efforts in making the best use of 3D printing in India. Fabheads has fabricated drones, robot parts, aerospace parts, and much more using 3D printing. Fabheads offers customized hybrid processes — combining the power, precision, and flexibility of Composite 3D printing with the time-tested traditional fabrication processes, we effectively create one overall fabrication process blueprint to make that part perfect — be it in strength, precision and cost-effectiveness!

We’d love to hear your thoughts on the future of 3D printing in the comments section.